How China Injection Molding can Save You Time, Stress, and Money.

Wiki Article

Fascination About China Injection Molding

Table of ContentsSome Of China Injection MoldingThe smart Trick of China Injection Molding That Nobody is Talking AboutRumored Buzz on China Injection MoldingThe Facts About China Injection Molding UncoveredSome Known Facts About China Injection Molding.What Does China Injection Molding Mean?

Little Design Errors Have BIG Costs with Shot Molding Ahead of time costs have a tendency to be very high as a result of style, testing, and tooling demands. If you are mosting likely to generate parts in high volumes you wish to make sure you get the design right the very first time. That is a lot more challenging than you could believe.

Be Ready for High Tooling Prices for Shot Molding Tooling is virtually a project per se and also only one stage of the whole injection molding process. Prior to you can produce a shot formed part you initially have to make and also model a part (most likely via CNC or 3D printing).

Things about China Injection Molding

As well as commonly after substantial screening in both of the previously mentioned phases, you get to injection mold and mildew a component. As you can picture, every one of the model required to obtain the tool proper previous to mass production needs both money and time. It is uncommon that you would model an injection molding device.This is incredibly challenging as well as in a lot of cases may indicate requiring to ditch the device (or part of the tool) completely as well as start over. In various other instances you may be able to weld steel into the dental caries that is undesirable. Attire Wall Surface Thickness is Essential Shot molding demands uniform wall thickness.

Keeping walls from being too thick is very important to avoid disparities in the cooling procedure leading to problems like sink marks - China injection molding. A great guideline is to keep walls less than or equal to 4mm thick. The thicker the walls the a lot more material you will certainly utilize, the longer the cycle time will be as well as the greater your cost per component will be.

Facts About China Injection Molding Revealed

For an example of a large shot molded component, consider the purchasing carts at Target. The machinery exists to mold and mildew very big pieces (e. g. 1000 lot presses about the size of a train's buggy), using it is very expensive. Consequently, things that are bigger than a typical injection molding device's ability are usually produced in multiple pieces.

Is Injection Molding the Right Option for My Project? Prior to you seek to produce a part using shot molding read here think about a few of the following things.

Examine This Report on China Injection Molding

From there, you'll wish to determine the number of components generated at which you anticipate to recover cost on your investment (consider the prices of style, screening, manufacturing, assembly, advertising and marketing, and also distribution along with the expected cost factor to buy). Construct in a conservative margin. And do not forget entrance prices.

Make certain you recognize this crucial point in advance. Next off, Allow's Talk Design Factors to consider When it involves component design, you desire to develop the component from the first day with injection molding in mind. Streamlining geometry and lessening the variety of parts at an early stage will certainly pay rewards down the road.

Top Guidelines Of China Injection Molding

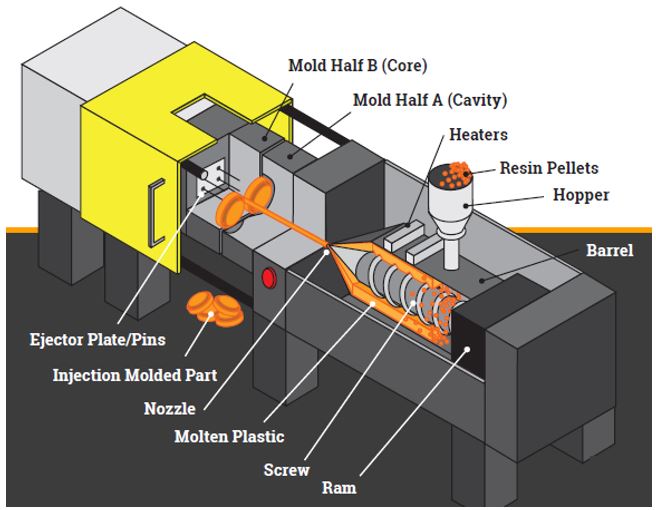

It is also helpful for completed models that are used for customer and/or product screening. Before this late phase in manufacturing, however, 3D printing is far more budget friendly and also adaptable for products in the early stages of design.Contents Shot molding is the most generally utilized production blog here procedure for the manufacture of plastic components. A variety of items are produced using shot molding, which vary greatly in their dimension, complexity, and application. The shot molding procedure requires using an injection molding machine, raw plastic material, as well as a mold.

The steps in this process are described in higher information in the next area. Shot molding is made use of to produce thin-walled plastic parts for a wide browse around this web-site array of applications, one of the most usual being plastic real estates. Plastic housing is a thin-walled unit, often calling for lots of ribs and also bosses on the inside.

China Injection Molding for Dummies

Process Cycle The process cycle for shot molding is very brief, commonly in between 2 secs and also 2 minutes, and also includes the adhering to four stages: Clamping - Before the shot of the material into the mold and mildew, both halves of the mold and mildew have to first be securely nearby the securing unit.The hydraulically powered securing unit pushes the mold fifty percents together and also applies adequate pressure to maintain the mold securely closed while the product is infused. The time needed to shut and also clamp the mold and mildew is reliant upon the device - larger makers (those with higher securing forces) will require even more time.

Report this wiki page